6 Dec 2014 - Making a Wide Panel

2. Flat, Square and Straight (discussed in a previous post) – This is critical. Use the jointer and table saw to get a perfectly square board and use the jointer and planner to get it straight and flat. If you start with bad boards, you'll end with a bad panel.

2. Flat, Square and Straight (discussed in a previous post) – This is critical. Use the jointer and table saw to get a perfectly square board and use the jointer and planner to get it straight and flat. If you start with bad boards, you'll end with a bad panel.

3. Get the Thickness Right – Get all the boards to the same thickness. There may be some more flattening to do once the panel is glued up, but this initial thicknessing of the workpieces assists in the glueup.

4. The width of each board within a panel may vary, but as a general rule, I try not to go much wider than 6" for any individual board—the width of my jointer. Wider boards may twist or cup. As for length, start with pieces 3" to 4" longer than the finished panel. This will allow some error during the glueup, and you can trim it to final size afterward.

5. Joint the Edges – Run each board one final pass over the jointer to surface the edges that will be glued together to ensure flat edges that will align perfectly.

6. Do a Dry Run – Before glue-up, it's best to do a test run by clamping the panel together first. This gives you an opportunity to reposition boards for a better grain pattern if needed or correct any edges that might not go together perfectly. Once you get it matched, mark the top of the panel with a large triangle across all the boards to correctly align the boards during the actual glueup.

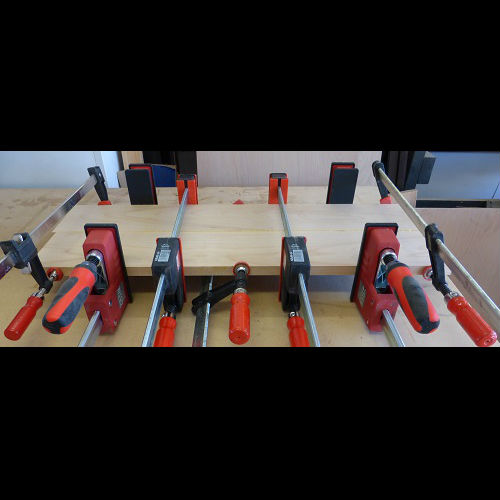

7. Set up - Gather all your supplies: glue, glue brush, wax paper, and set the clamps that will go beneath the panel in position. Have clamps to go over the panel opened up and ready. Set the boards on edge, and brush a layer of glue onto one edge for each mating joint. Set the boards face down and begin to add the clamps. Assemble the panels by alternating the clamp position – one clamp under the panel, one over the panel to get even clamping pressure. As you tighten the clamps makes sure the lines of the triangle are aligned. Use a dead-blow mallet to move boards into position. You may even want to clamp the ends of the panel with a caul to keep them flat. There should be some glue squeeze-out on the joint lines of your glueup. To remove this, wait about an hour, remove the clamps, and then scrape the partially set-up glue from the surface.

7. Set up - Gather all your supplies: glue, glue brush, wax paper, and set the clamps that will go beneath the panel in position. Have clamps to go over the panel opened up and ready. Set the boards on edge, and brush a layer of glue onto one edge for each mating joint. Set the boards face down and begin to add the clamps. Assemble the panels by alternating the clamp position – one clamp under the panel, one over the panel to get even clamping pressure. As you tighten the clamps makes sure the lines of the triangle are aligned. Use a dead-blow mallet to move boards into position. You may even want to clamp the ends of the panel with a caul to keep them flat. There should be some glue squeeze-out on the joint lines of your glueup. To remove this, wait about an hour, remove the clamps, and then scrape the partially set-up glue from the surface.

8. Multiple Glueup Approach – For a small panel, one glueup may complete the job. A different approach to larger panels, though, is to make smaller glued-up panels first. This lets you focus on one or two joints at a time. Plus, you can put the smaller panels through your planer one more time before gluing them together into a larger panel.