7 Jan 2026 Oak Sewing Table

I recently built this very large (total 60” x 48”) sewing table for my spouse. I used distressed oak that occurs from disease or insects and causes the dark streaks

I recently built this very large (total 60” x 48”) sewing table for my spouse. I used distressed oak that occurs from disease or insects and causes the dark streaks

It was a long November with lots of travel and family activities so no posts. From 1 – 21 Dec 2025 there is a special show for Christmas in the

About 10 days ago, I started building two boxes. One is cherry with a maple and purple heart inlay, and the other is walnut with rosewood and walnut inlay (meant

Over the past couple of weeks, I built this perfectly-sized storage cabinet using knotty alder. It has tongue and groove sides with simple frame and panel doors and three sturdy

Upcycled Pine Last week, a good friend asked if I could help her build a barn door-style door. I’ve built a few and knew it wouldn’t be too hard a

19/38 Drumsander and 8” Helicalhead Jointer During COVID, I got a drumsander. In the past when I’ve needed this resource, I’ve paid one of the cabinet shops in town to

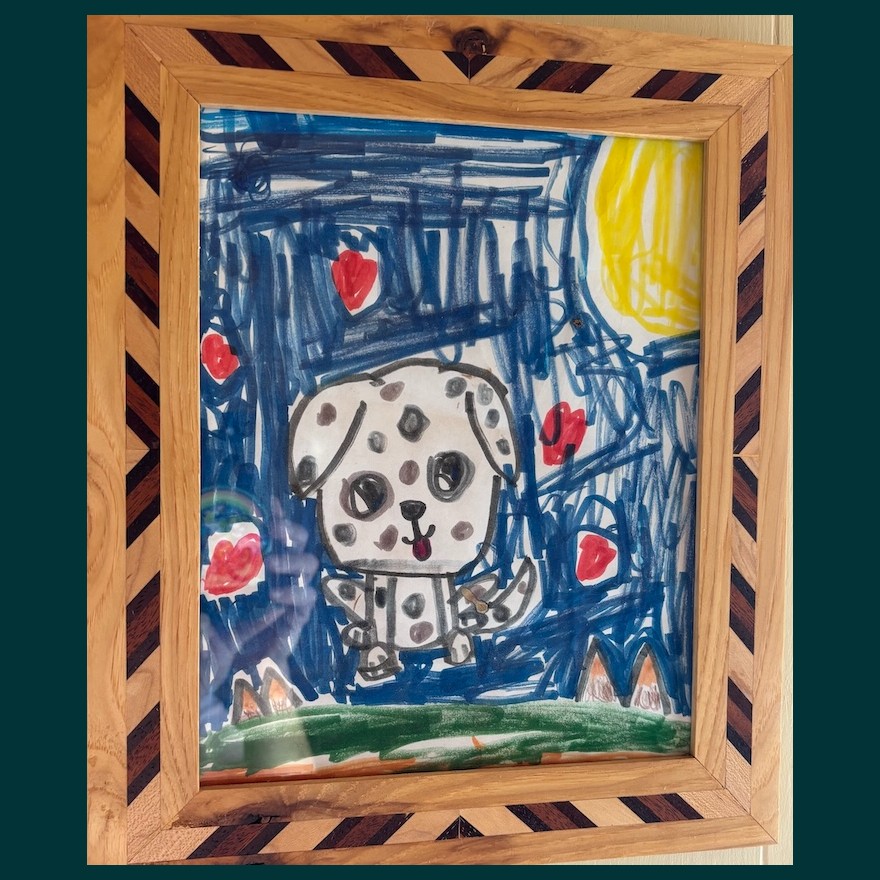

Hickory and Exotics Several years ago, I started making picture frames for the cabin with a ½” inlay in the 1 ½” wide hickory frame. I created the inlay with

In May, I retired with 37 years of service in the Air Force. It was an amazing career with 20 years of active duty service and 17 years as an

I created another gift project! About three months ago, I retired from federal service, and I’ve been loving every minute in the shop. I’ve mostly been working on projects for

I’ve been building wooden gift items for several years now, when I’m not working on a commission. Additionally, the excessive cost of wood due to COVID has caused me to

I recently built this very large (total 60” x 48”) sewing table for my spouse. I used distressed oak that

It was a long November with lots of travel and family activities so no posts. From 1 – 21 Dec

About 10 days ago, I started building two boxes. One is cherry with a maple and purple heart inlay, and

Sign up to be notified of local craft events where I’ll be present, special prices for gift items, or discounts on large furniture projects.