27 December 2013 Hits: 6498

“Be Careful” There are too many projects to be built to be limited by even a small injury.

“Be Careful” There are too many projects to be built to be limited by even a small injury.

It is so easy to lose focus and come close to an accident. I have read so many wood magazines and looked at so many woodworking blogs, I sometimes get sick of seeing all the stuff about safety. I've been around long enough to know how dangerous woodworking is so why do I have to read a safety article in nearly every edition of every magazine I read. You may be thinking the same thing as you read this. The reason is as obvious as all the safety tips we read over and over – no matter how many times you read about it and no matter how hard you try to follow every single safety rule, we all get a little distracted once in a while. Often there are several things on your mental list to do, and it is easy to lose focus even for a second. Also we live in a society where if you can't multi-task, you are not efficient.

20 December 2013 Hits: 6005

“Wood Movement” A problem that can't be denied—wood moves!

“Wood Movement” A problem that can't be denied—wood moves!

No matter what you do, the wood in your projects is going to move as the seasons change. I learned the hard way like most woodworkers when I watched one of my beautifully constructed pieces of furniture split. The joint was almost seamless right up until the humidity changed, and it split right down the middle. I knew about wood movement. I had read about it in nearly every article or project plan I had ever looked at. I just thought they were making a bigger deal out of this little wood movement issue. Over the past five years of building projects I've begun to understand just how big of an issue it is. You MUST account for wood movement regardless of the size of the project. As humidity changes the cells in the wood swell or shrink. The worst part--it does it randomly depending on the wood, the amount of humidity and probably a million other factors beyond the scope of this blog. The one thing you can count on is that generally the movement occurs across the grain. Also plywood is pretty stable because of the way it is put together with alternating grains with each ply so there is a less of a concern about wood movement.

29 November 2013 Hits: 6265

“Dust Protection” Find good dust protection.

“Dust Protection” Find good dust protection.

I don't have a dust collection system. I know I need one, but it is not quite in the budget just yet. I use my shop vacuum and that helps, but my shop is always very dusty. Until I can make arrangements to be able to collect the dust at the source, I know I need to wear some type of dust mask. I hate them as much as the next person, but I know how important it is to wear one. I have tried all kinds from paper masks to heavy obtrusive face respirators. I didn't feel like the paper masks were very effective. I have a pretty small head so it was difficult to find a respirator that would fit well and wasn't too heavy. Finally, I found one that works great, the North 770030 Silicone Respirator Half Mask – it is a Honeywell product. When it is used with the particulate cartridge it is light and unobtrusive. It also fits a gas and vapor cartridge.

22 November 2013 Hits: 6145

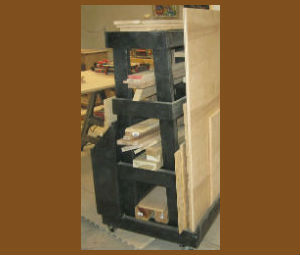

“Mobile Wood Storage” Great storage for a small space.

“Mobile Wood Storage” Great storage for a small space.

One of the smartest space saving projects I ever created for my small workshop was a mobile lumber and sheet good storage rack. I built mine based on a modified design from a pattern in Woodcraft Magazine. The pattern can be downloaded at Woodcraft. Even if you are a beginner, you probably don't need a pattern, but check out the pattern for a reference. The first I did to modify the original was to make it a little smaller; full size would have been nice, but I just don't have the space for it. I also created little bins on one side. I often have small cut offs that are still useful but are too short to store any other way.